CRAFTMAN SHIP

創業から70年、奥山メリヤスが培ってきたノウハウと技術はBATONER製品の中に活きています。ニッティング、リンキング、ステッチング、プレシング、チェッキング、大きく分けると5つの工程によってニットは完成します。世界でも有数の機械、昔から変わらない手作業、職人の経験と知識、それらを組み合わせることによってBATONERのクラフトマンシップは発揮されます。原料の糸からお客様の手に届くその瞬間まで、気を抜くことなく製品と向き合っていくことがBATONERの使命です。

Since more than 60 years of its establishment, the know-how and techniques OKUYAMA MERIYASU has cultivated are alive in BATONER’s products. When broadly classified, knitwears are completed in five processes of knitting, linking, stitching, pressing, and checking. BATONER’s craftsmanship manifests itself by combining one of the best machines in the world, handwork that has not changed since the old days, and the experience and knowledge of the artisans. BATONER’s mission is to handle the products with care without losing focus from yarns that are raw materials to the moment it is delivered to our customers.

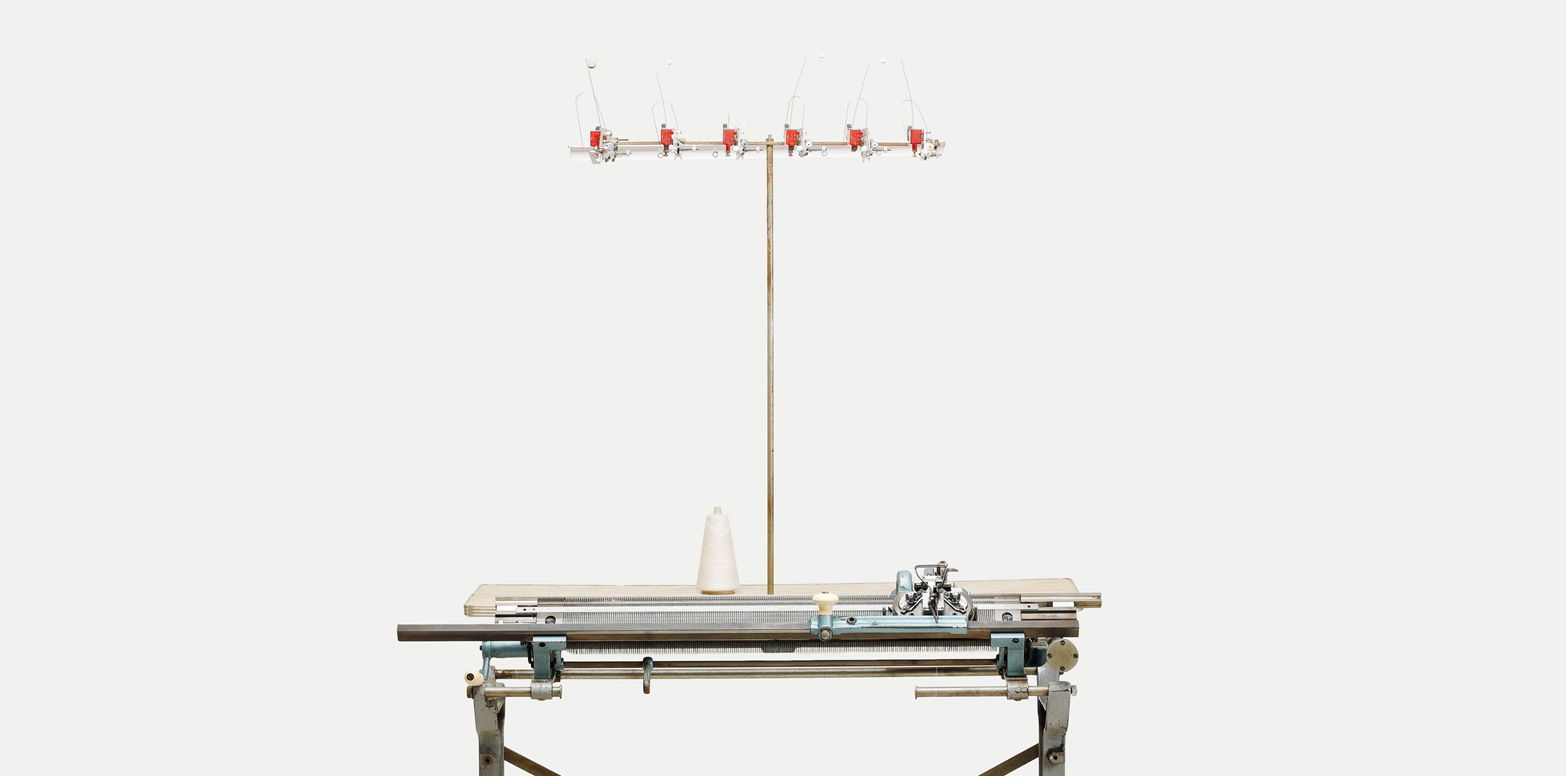

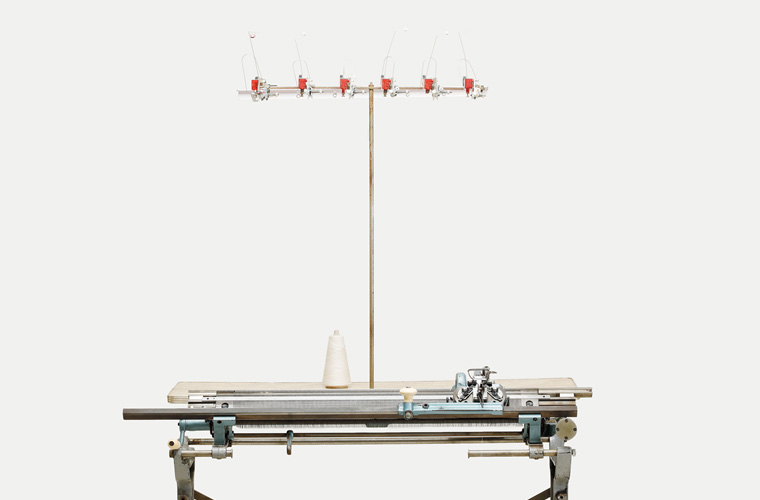

1. KNITTING

糸からニットの原型となる各パーツを編み上げるニッティングの工程として、成型編みと呼ばれる技術を採用しています。

様々なゲージの針を用いることで、見た目がしっかりと重厚感のあるローゲージニット、着心地が軽やかなハイゲージニットなど、たくさんのバリエーションを持った製品を作り上げていきます。

We use a technology called form-knitting for the process of knitting each part which becomes the prototype of the yarns becoming knitwears.

By using various gauge needles, we create products with many variations, such as low gauge knits with a sturdy and bulky appearance and high gauge knit with a lightweight comfort.

2. LINKING

前身頃、後ろ身頃、袖、襟といったパーツをひとつひとつ手作業で繋ぎ合わせる工程をリンキングといいます。

細かい作業のため時間がとてもかかるのですが、丁寧に縫製するので製品の継ぎ目が目立たず、正確な柄合わせも可能になります。

現在ではリンキングをできる職人が減ってきているため、貴重な縫製技術です。

The process of connecting each part by hand such as the front body, back body, sleeves, and the collar is called linking.

Although it takes a lot of time as it is detailed work, the seam will not stand out, and accurate pattern matching also becomes possible.

It is a valuable sewing technique, as artisans who can perform linking are currently decreasing.

3. STITCHING

ニットを編む上で必要不可欠な作業が糸始末(ステッチング)です。

鋏、毛抜き、糸通し、べら針、リッパーと呼ばれるこれらの道具を用い、ニッティングの工程で必ずはみ出てしまう糸を編み地に戻したり、余分な糸をカットします。

そうすることで糸のほつれがなくなり、綺麗な見栄えかつ丈夫なニットに仕上がります。

Stitching is an indispensable work when knitting knitwears.

It cuts extra yarns and puts back yarns into the knitted fabric that will inevitably protrude in the process of knitting, using tolls called scissors, tweezer, needle threader, latch needle, and ripper.

By doing so, the fray of the yarn disappears, and a sturdy knitwear with a beautiful appearance is made.

4. PRESSING

ニットの形が出来上がってもまだ完成ではありません。糸の組織を水で湿らせ、熱や圧力を加える縮絨という作業を行います。

そして様々な型枠を使ってアイロンをかけます。縮絨することで変化する寸法を正確に出し、意図したデザインや風合いに仕上げる職人の感覚的な仕上げ作業です。

Knitwears are not completed even after the shape is completed.

A process of damping the yarn tissues with water and applying heat and pressure called fulling is applied. It is then pressed with an iron using various molds.

It is a sensuous finishing work applied by artisans that create accurate dimensions that change with fulling, in addition to the intended designs and textures.

5. CHECKING

最後に行うのが検品(チェッキング)です。編み地が落ちていないか、傷や汚れがついていないか、人の目で一枚一枚確認します。

問題がなかったらここで初めて製品と認められ、出荷されます。

これらの工程ひとつひとつを職人が自らの手で丁寧に行うことでBATONERのクオリティが維持されているのです。

The last process applied is checking. We check each piece with our own eyes whether the knitted fabric is loose or whether it has scratches or stains.

If there are no problems, it is recognized as a product for the first time which is then shipped.

The quality of BATONER is maintained by artisans carefully applying each of these processes by their own hands.